On a good day, all the customer cares about is the end result of a shiny car. The steps and science it takes to actually remove all of the contaminants from a car, including dirt, grime, oil, gas, etc., are typically of little concern to the satisfied consumer. However, the factors it takes to apply chemicals to a car should be of concern to professional carwash operators who are looking to achieve consistent, quality results.

We spoke with one expert, Matt Brandt, industrial products sales manager with DEMA Engineering Co., to see what he considers to be the five most important factors to carwash chemistry.

Creating synergies

Chemical products are made up of complex formulations that can clash or work more effectively with other products. It’s important to source your professional carwash chemicals from trusted suppliers and manufacturers. Use their expertise to create synergies among the products and equipment you purchase.

According to Brandt, the “chemical compatibility of components” is one of the top five factors to perfect chemical application. “Ensure that your chemicals are not going to cause maintenance problems with other items in the wash,” he adds.

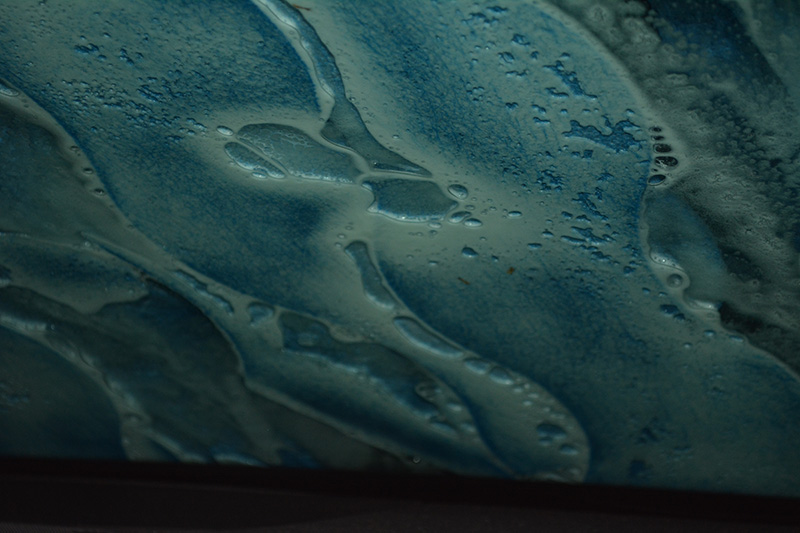

Put on a show

For many customers, visiting a carwash can be a fun — even relaxing — experience. With advanced LED lighting, foam and colored soaps and waxes, as well as other entertainment elements, leading professional washes are tapping into customers’ senses to create a show at the carwash, which Brandt calls the second most important factor to applying carwash chemistry today.

“It’s important that operators make sure that customers have the proper feel of getting value for what they paid, and that includes ensuring that your equipment is putting on the best show it can by maintaining components.”

Dilution

According to Brandt, the third most important factor to proper chemical application is dilution control. Here, especially when deploying a new type of chemical product, operators should follow manufacturer’s recommendations for dilution and delivery and then visually inspect cleaned cars throughout the day and week.

Since every wash is different and water quality varies, adjustments might be needed. “The key,” explains Brandt, “is not leaving a residue because too much chemical was applied and not cleaning the car effectively because not enough chemical was applied.”

One common mistake that he sees is that operators don’t apply enough chemicals for a variety of factors, including perceived savings. Again, it’s best to follow the manufacturer’s recommendations and then adjust as needed based on results.

Safety

As regulated, many chemicals must bear specific labels and warnings, and employees must be trained to identify and then follow caution when handling certain chemicals. Having first-aid kits and eye wash stations available at your site is recommended. Since risk is elevated, employee safety is listed as a top factor to consider when applying chemicals at your carwash.

“Use chemistry that is safe for employees, and know the proper exposure and personal protection equipment that is needed,” advises Brandt.

New innovations

Manufacturers and chemists are constantly working on improvements for existing chemical products while also developing new products as technologies and science evolve. In fact, some chemicals that were used in the professional carwashing industry decades ago, most notably those that contained hydrofluoric acid and ammonium bi-fluoride, have been shunned by our industry’s leading advocates.

Therefore, adapting to new products is a top factor that all operators should consider, regardless of any loyalty to one specific product or chemical line.

“Test out new products to see what works the best,” notes Brandt. “It is always important to stay in the know about what new products are available from manufacturers and what the latest innovations are in chemicals.”

Friction versus touchless

While the noted factors to maintaining chemistry application to achieve consistent, quality results can be used across all wash formats, there are some other considerations for certain segments of the industry.

The most notable difference depends on whether your tunnel or bay is offering a friction or touchless service. Equipment, maintenance and chemistry are different and again, reputable manufacturers and suppliers will be able to match your wash to the proper chemicals needed.

“This is a timeless debate — friction or touchless. There are four main factors to cleaning, no matter if you are cleaning your clothes at home or a vehicle in a carwash,” educates Brandt.

According to Brandt, these four main factors to cleaning come down to the acronym T.A.C.T.: time, (mechanical) action, chemical and temperature.

“Those are the four factors you can control. When you increase one of these, such as using additional brushes to create more mechanical action in a friction wash, you can decrease in some of the other areas, including faster operation, less hot water and leaner chemical applications,” continues Brandt. “If you have a friction system, you may be able to adjust one of the other factors to help make your wash most effective.”

For a touchless system, adds Brandt, you may need to adjust some of the other factors to make your wash most effective. “Bottom line is that every wash is going to be set up a little bit different when you change out the components of your wash,” he concludes.

Reading trade publications and researching the carwash chemical market are great first steps to take when looking to elevate your chemical application in 2019. There is more competition for carwashing now than compared with recent decades, and carwashes that fail to deliver a quality experience with even better results by perfecting chemical applications will lose business.