Many detailers encounter noticeable swirls and scratches on a vehicle’s finish; the common question is what are they going to do about it?

A good answer for many detailers involves buffing and reconditioning treatments, which go hand-in-hand with producing that perfect finish.

Swirl stress

- Using dirty towels or sponges;

- From harsh chemicals; and

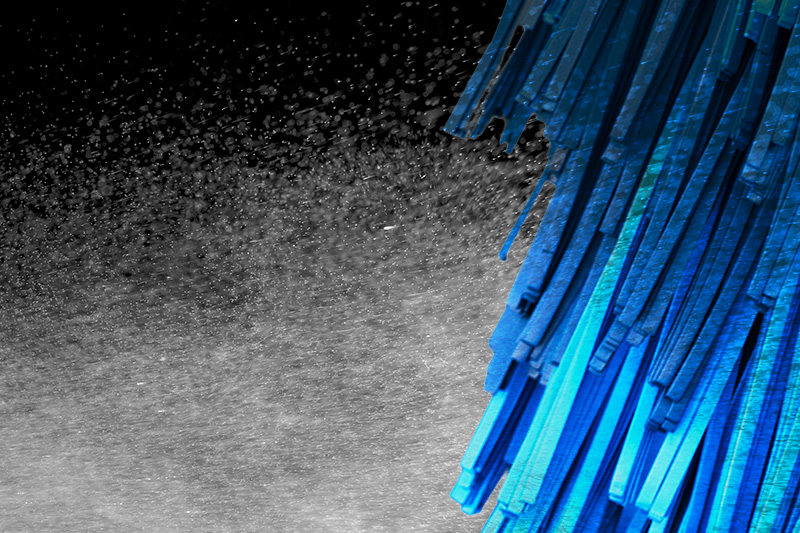

- Sometimes even carwashes.

New finishes may even contain swirls. Once they are there, swirls are very difficult to remove, but there is hope.

However, many times if a detailer attacks the swirls or scratches with aggressive compounds or pads the situation becomes worse. Using the right products will help combat the swirl mark enemy successfully.

Knowing what to use

Another good idea, which can ease the process, is to ask a knowledgeable salesperson from the company that provides the reconditioning supplies. This person is generally factory trained and is well-informed by the manufacturer he or she represents.

The best advice, regardless of the direction taken when selecting a pre-cleaner or compound, is to start with a very light abrasive product.

If the light cut does not totally remove the scratches or swirls move to the next most aggressive product and so on. Pre-cleaners always contain some fine abrasives to remove swirls and create gloss.

Pre-cleaners can be used alone or following compounds. Compounds are generally more aggressive. Most reconditioning product manufacturers offer pre-cleaners and compounds in several levels of aggressiveness.

Choosing the right pre-cleaner and/or compound means the detailer can control the depth and degree of the buffing action to suit the conditions of the vehicle’s paint and the techniques used.

Buffing to beautiful

Buffing pads: As with the right chemical choice, the right buffing pad is just as important. Using the wrong (or worn-out) pad can put even more scratches or swirls on the finish.

Whether you chose a wool or foam pad, check again with the supplier as to the recommended product to use with a particular pad. A top-quality scratch and swirl remover can certainly produce unsatisfactory results if used with the wrong type of pad.

As with the pre-cleaner/compound do not use a more abrasive pad than necessary. Start with a light to medium cut or polish pad.

Increase the aggressiveness of pad choice as necessary. Look also for manufacturers of pre-cleaners/compounds/polishes and buffing pads which use a color matched system of matching the best product to the best pad.

The pads should be in excellent condition, even if it means using a new pad for each vehicle.

Trying to save a few bucks by over-extending the useful life of the pad also increases the chance of leaving swirls behind by using old, worn-out and damaged pads.

For example, a foam finishing pad can become as aggressive as a foam cutting pad over time as the finishing foam wears down and the pad surface becomes worn.

Technology triumphs

The high speed action of the machine along with the heat it generates creates a huge advantage over hand waxing.

Variable speed or dual-action (DA) buffers do a better job of cleaning deeper and removing deep scratches and heavy swirl marks.

A slower speed (1000 – 1800 RPM) is recommended most often to effectively remove scratches and swirls. The low speed forces the oil and abrasives from the cleaner deeper into the surface for better work time and control over the area being buffed.

The DA type buffer can produce great results. This buffer is generally smaller in size and uses special foam buffing pads.

The dual action of this buffer allows the product and pad to remove the scratches and swirls, and when polishing the finish any possibility of swirl marks is virtually eliminated.

Eliminate the enemy

Strive to use the correct pad, chemical and technique for the situation at hand. It can greatly reduce the amount of swirl marks left behind.

Always keep in mind — each vehicle will buff differently. Work with a clean surface. Keep the pads clean. Use small amounts of product and keep the buffer flat to the surface.

Keep the RPM down and use little or no downward pressure. Then step back and look at the finish — looks great, doesn’t it?

Don Cornelius is president and co-founder of Distinctive Details, Inc., a manufacturer of products for detailers and carwashes worldwide. Cornelius, a 35 year veteran of the automotive aftermarket, has been associated with the detail industry for almost 20 years. Don can be contacted at [email protected].