Today’s high-efficiency softeners are changing the economics of water softening in the carwash industry. Traditionally, the savings have been based largely on reducing chemical and detergent costs. While those savings are still significant, new commercial softening technology using multi-tank systems (MTS) also offers significant water and salt savings.

According to the Canature WaterGroup Commercial Industrial Engineering Division, an MTS uses 40% to 50% less regeneration water and salt compared to conventional softening systems. Rather than a large, single tank or twin alternating system that has been sized to handle peak flow rates, an MTS uses a series of smaller tanks to efficiently adjust to your business’ flow rates throughout the day. During periods of high flow demand, tanks come on-line to add flow rate capacity. During periods of low flow demand, tanks go off-line. This new approach to softening is called responsive or progressive flow technology, and it’s arguably the most important innovation in commercial water conditioning in the past 50 years.

Whether your carwash is in the market for a new softener or has an existing system, this technology makes investing in a new MTS with responsive flow worth a second look.

The economics of softening: performance and protection

Before we dive into how a new MTS can save you money, it’s important that we start with the basics.

Water softeners add value to your operation by protecting your water-using equipment from poor performance and premature failure. Some hard water problems are very visible, like sprayers and dispensers becoming clogged. Other problems can go undetected, like scale on water heater elements and buildup in reverse osmosis (RO) membranes. Visible or invisible, these problems have real costs associated with them. Clogged fixtures cause replacement or refurbishing costs and can frustrate your customers. Scale buildup in your water heater will inflate your energy bills, and prematurely damaged RO membranes will leave you with unnecessary replacement costs. Soon, these small costs can add up to make a real impact on your bottom line.

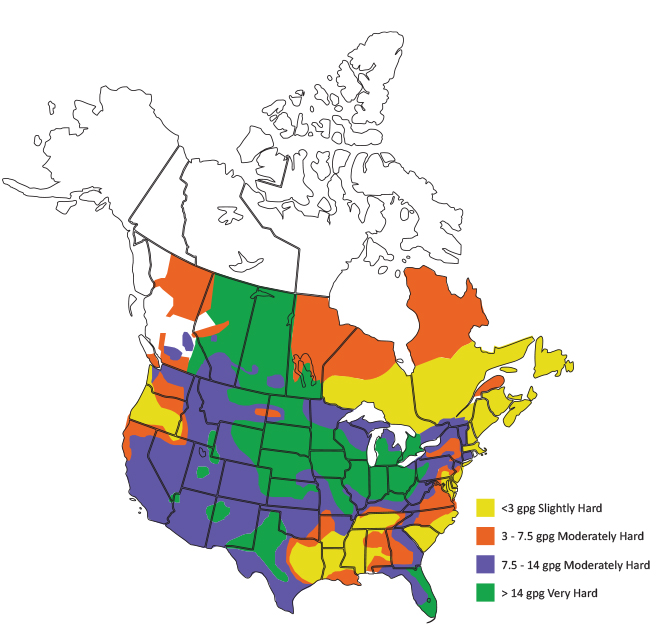

You can also depend on water softeners to reduce your daily operating costs by saving detergent and allowing you to use lower water temperatures while maintaining a high-quality wash. Water hardness, measured by the grains per gallon (gpg) of magnesium and calcium in the water, varies across the U.S. from slightly hard (<3 gpg) to very hard (>14 gpg).

According to the Water Quality Research Foundation’s Softened Water Benefits Study, soft water can reduce detergent use by as much as 50%. Let’s look at what these detergent savings can mean for your carwash in the following example:

- Detergent and chemical costs per wash

- Basic carwash: $0.45/car

- Deluxe carwash: $1.20/car

- Average wash cost: $0.64/car

- Estimated detergent/chemical costs

- $0.64 × 55 washes/day = $35.20 (estimated daily cost)

- $35.20 × 365 = $12,848 (estimated annual cost)

- Potential annual detergent and chemical savings

- $12,848 × 0.5 = $6,424 (estimated annual savings in a market with hard water).

An effective softener can reduce annual detergent costs by more than $6,000. Many business owners presume that because they have a softener installed, they are already realizing these savings. But, that is not always the case. If you haven’t tested the softness of your water since the system has been installed, you may be surprised by the results.

I’ve been to many carwashes that have a softener, and to the surprise of the owners, the water tests hard even after having gone through the softener. Usually, this is because the system is outdated or not working properly. Whatever the reason, you can be missing out on the benefits of soft water without even knowing it.

If your system has been part of your operation for a number of years, it is worth your time to have the water tested periodically. It’s a quick and easy way to make sure your equipment is doing its job and that you’re not spending more than you should on detergents and chemical.

Now, let’s turn our attention to how an MTS using responsive flow technology can take those savings one step further.

High-efficiency softeners

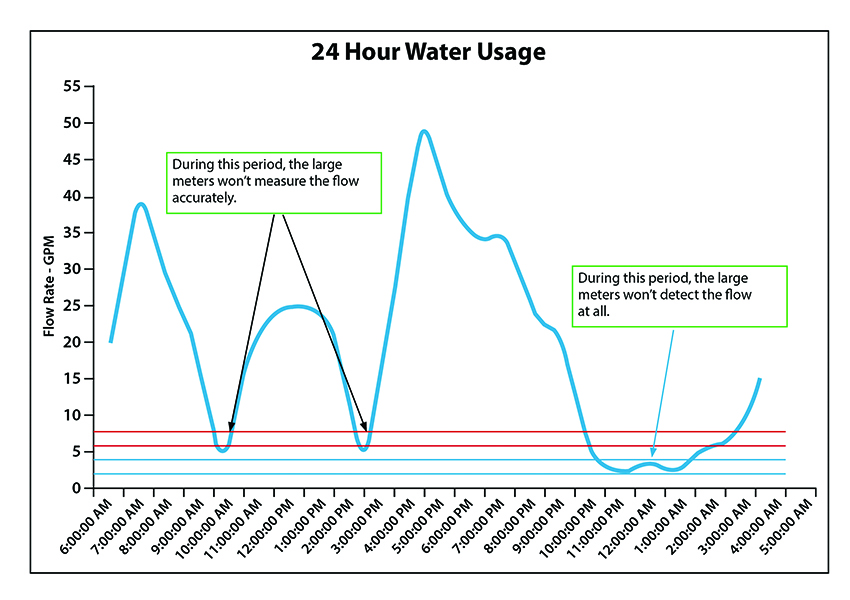

If your business already has a commercial water softener, there’s a good chance that it is a large single or twin alternating system. These softeners work as planned when your business is operating at full capacity, but during periods of low demand (6 gpm or less), a 24-inch tank softener with a 2-inch control won’t meter, and water can channel through the resin.

Channeling occurs when the incoming hard water follows a narrow path through the softener’s resin bed and does not exchange ions with the resin, leaving your water unsoftened. If you’ve ever noticed that the busier your business is, the better your detergent works, the culprit could be an oversized softener.

Related: The cold, hard facts about water

A commercial MTS with responsive flow technology will continue to soften water at flow rates of less than 2 gpm while still being able to handle high flow rates as well.

Responsive flow technology works by continuously bringing tanks on-line and off-line in response to the water demands of your carwash. For instance, in a four-tank MTS setup with responsive flow technology, only one of the four tanks is needed to soften water when the carwash isn’t busy. However, more tanks come on-line as the wash bays fill up. This responsive design allows the MTS to use up to 50% less salt and 38% less regeneration water than conventional single-tank or twin alternating systems.

Saving operating and capital costs

Let’s put these savings to work in the carwash scenario, starting with the investment cost. A large two-tank system with brass valves will retail around $13,000. An MTS designed to service the same building will retail around $10,000 — a 30% savings.

So far, we’ve saved $3,000. Let’s look at our operating costs.

According to www.statisticbrain.com, carwashes use an average of 38 gallons of water per wash and process an average of 55 washes per day. This equates to 2,090 gallons of water per day and 762,850 gallons of water per year.

A traditional commercial softener removes 2,000 grains of hardness per pound of salt. An MTS with responsive flow design is twice as efficient, removing 4,000 grains of hardness per pound of salt, thus cutting salt use in half.

Let’s apply this example to a carwash in a 20-gpg hardness market and assume a 40-pound bag of salt costs $6:

- Hardness grains to be removed each year: 762,850 gallons × 20 gpg = 15.26 million

- Traditional softener: 15,257,000 ÷ 2,000 = 7,629 pounds of salt required ($1,144)

- MTS softener: 15,257,000 ÷ 4,000 = 3,814 pounds of salt required ($572.14)

- Savings: 3,814 pounds of salt and $572 per year.

As the hardness in the water increases, so does the annual savings. In a 40-gpg hard water market, salt savings alone can reach $1,144 per year.

Now, let’s add in the water savings. If conserving water hasn’t been much of an economical concern for your business yet, it probably won’t be long before that changes. According to a recent annual study by U.S. independent insight firm Bluefield Research, water bills in 50 U.S. cities have gone up 31% since 2012 — a trend that isn’t likely to reverse in the future.

A traditional commercial softener will send 35,600 gallons of regeneration water to the drain in a 20-gpg market. Regeneration water is the water used to replenish your softener’s resin bed with sodium ions so it can soften water. In comparison, an MTS in a 20-gpg market will send 22,250 gallons of regeneration water to the drain. That means 38% less water going to the drain. At $0.01 per gallon, you’ll save $133 per year on water.

- Total Savings over a 10-year period:

- + $3,000 (capital savings)

- + $5,720 (salt savings)

- + $1,330 (water savings)

- $10,050 (the cost of a triplex MTS unit)

Make soft water part of your business plan

The value of soft water to the carwash industry was recognized long ago. The opportunity now is to install a softening system that is more economical and uses the most advanced technology. An MTS with responsive flow design can lower your capital investment in equipment, decrease your operating costs and is designed to allow you to easily add tank capacity down the road as your business grows. The savings are there, and at the end of the day, doesn’t it just make good sense?

Jeff Hubbard is the director of business development commercial products, U.S. for Canature WaterGroup. With 28 years of industry experience and nearly a decade with Canature WaterGroup, Jeff has an in-depth knowledge of water treatment with a strong background in training, sales, service, application and troubleshooting. You can reach Jeff at [email protected].