Since the inception and use of reclaim water in the carwash industry, the dirtiest, filthiest, most dreaded — but definitely required maintenance operation was and still is pumping out the reclaim tanks.

Pump up the sludge

If your in–bay automatic carwash generates any amount of volume you should be pumping out the reclaim vaults every three to four months. For some 40 to 50 years, carwash operators have been told that this sludge and sediment is considered to be hazardous material and must be tested and dumped at a regulated hazardous waste site provided by your local authorities. For all these years, most operators have just gone ahead and paid as much as $3,000 and sometimes more for the cost of this service in order to obey the law.

As a manufacturer of an automatic sludge and sediment system I was curious to see if any of this was true. What we have found in just about all carwashes is this: Other than varying levels of petroleum hydrocarbons, none of the several sites we tested have high enough levels of hazardous material to be considered hazardous waste.

Is it really hazardous?

Recently, I had a long conversation with one of the groups in charge of waste water compliance for the state of Oregon: Department of Environmental Quality (DEQ). What they have found at the several carwashes they tested over the past years is that none of them had large enough amounts of foreign material to be classified as hazardous waste. This is not to say that carwashes in certain areas of the country do not have varying levels of hazardous material.

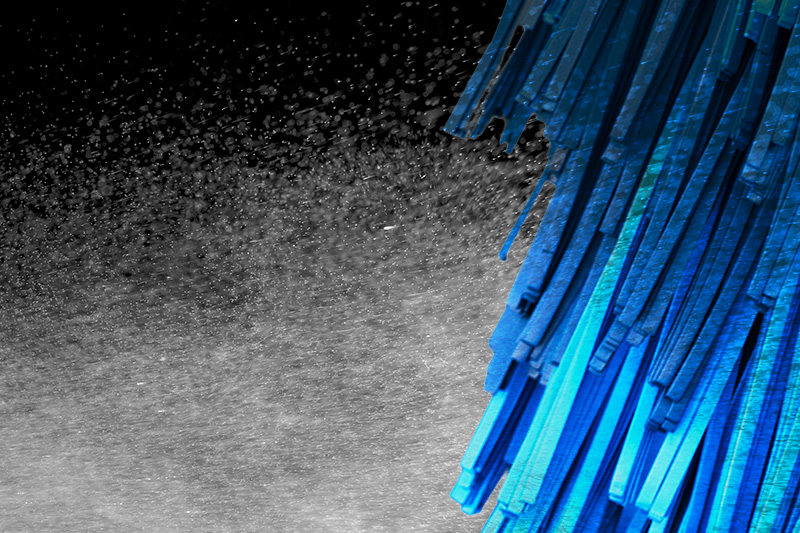

Many of the carwashes here in Oregon as well as other parts of the United States have chosen to have the sediment and sludge removed as part of their normal maintenance. Pumps are placed in the reclaim vaults/pits which are activated for 30 to 40 seconds every hour. The sludge and sediment is pumped into filter bags that contain the sludge and sediment and then returned water back to the reclaim area. These filter bags, when half full, are placed on a sturdy pallet, left to dry for a few days and then disposed of in the dumpster.

Keep in touch with the DEQ

When you have your reclaim vaults pumped, I suggest that prior to disposing any sludge or sediment on your own that you ask to receive a copy of the hazardous waste permit for the carwash. This way you will have an actual copy of what foreign materials are in the sediment/sludge and what levels are acceptable.

The Environmental Protection Agency (EPA) and the DEQ are primarily concerned with high levels of petroleum hydrocarbons. If the petroleum hydrocarbons are over the acceptable level then they can easily be controlled with the introduction of enzyme/bacteria that consume and eliminate the waste by turning it into harmless carbon dioxide and water.

Prior to leasing their retail locations, one of the major oil companies here in the Northwest tested on–site carwashes for hazardous waste and all were found to be compliant. This would lead me to believe that either we have clean sludge here in the Northwest, which I doubt, or we all have been supporting the sludge removal companies for a whole lot of years.

Consider automatic removal

In the current economic environment and with carwash volumes on a downhill slide, the operator must now seriously consider any and all other alternatives to improve the bottom line. One carwash operator that I know has been implementing an automatic sediment/sludge removal system for more than seven years with outstanding results.

Dan Krominga, owner of Carl B Clean, offers the following advise. “When we had to pump out our reclaim pits every three to four months at a cost of $1,500 to $2,000 each time, we soon began to realize that there must be a better way,” he said.

Krominga said it was cost prohibitive and required a lot of time and he needed to find another solution. “As luck would have it,” he said, “we were approached by a company offering a new alternative. Rather than having our reclaim tanks pumped completely dry and having to start over again, why not eliminate only the sludge and sediment and save money at the same time.”

Krominga had the automatic sediment/sludge removal system installed and he has now have saved over $30,000 in pumping fees alone. “We have only pumped the reclaim once in seven years and that was only because we installed new carwash equipment. I strongly recommend a system such as we have to anyone using reclaim in an exterior/full–serve tunnel, automatic–rollover or self–serve carwash.”

Andy Pazz has been in the carwash industry more than 35 years and is the owner of Laguna Ltd. He has written a book, How to Build An Exterior Carwash. For more information on that book, visit www.car-wash-business-pro.com.