In the carwash industry, every day presents a new set of challenges. Even the most prepared operator can struggle to provide the best wash results at an attractive price point while properly managing equipment upkeep, business records and employee relationships. Maintaining momentum can be even more difficult when auto manufacturers throw production curveballs at carwashes.

Two examples are the softer clear-coats and new paint formulations applied to vehicles. The finish and paint changes — and the subsequent problems they caused — left many customers wary of using previously popular in-bay automatic (IBA) friction equipment. Like every type of carwash technology, IBA friction washes — and the equipment companies themselves — evolved and advanced. Now, a selection of updated wash offerings is available to all bay carwash operators.

For many IBA carwashes, results are tied directly to the wash media used to clean vehicle surfaces. To help owners get the most out of their businesses, friction IBA experts stand ready to share information on brush options and additional wash advances.

In this article, we’ll find out more about the best practices these experts recommend to keep today’s IBA locations effective, safe and functional.

Continued evolution

Updated IBA sites that use wash media to clean vehicles are seeing continued equipment evolution via multiple available upgrades. These improvements involve many aspects of typical wash operation, including overall wash speed, adding new services and improved brush materials.

The IBA friction evolution that Tom Hobby, president of AUTEC Inc., first highlights is the development of faster wash equipment. This efficiency can provide IBA locations with a comparatively extraordinary throughput while delivering the cleanest vehicle possible. This evolution has allowed an IBA the ability to deliver 25 to 35 vehicles per hour without prep or attendants on-site.

Steve Robinson, vice president of marketing for Mark VII Equipment Inc., points to another IBA innovation that now allows washes to offer a polish program. After the equipment’s cleaning passes are complete, a special polish chemical is applied and buffed into the paint by the foam brushes. This application provides hand wax quality in just a fraction of the time. That said, operators must ensure that the IBA system purchased is capable of providing this add-on service.

A foam curtain application with multicolor LED lighting functions has also become a popular option for friction IBAs in recent years. Further, manufacturers have introduced hybrid machines that combine friction and high-pressure washing, Robinson notes. These systems have enabled operators to offer both soft-touch and touch-free wash packages via the same equipment. This combination means a location can appeal to a broader range of customers to help grow its business.

Damage prevention is another area of advancement in updated IBA washes. Hobby states that washes with gentle hydraulic operating systems can prevent damage that may occur with other types of friction washes. Another change that has helped prevent damage problems with customer vehicles is the upgraded wash materials used in modern IBA brushes.

Today’s wash media

Some friction IBAs designed in earlier decades used brush materials that attracted and held dirt, according to Robinson. This scenario risked damage to vehicle finishes. Other operations used material that was safer but could leave visible streaks on the car.

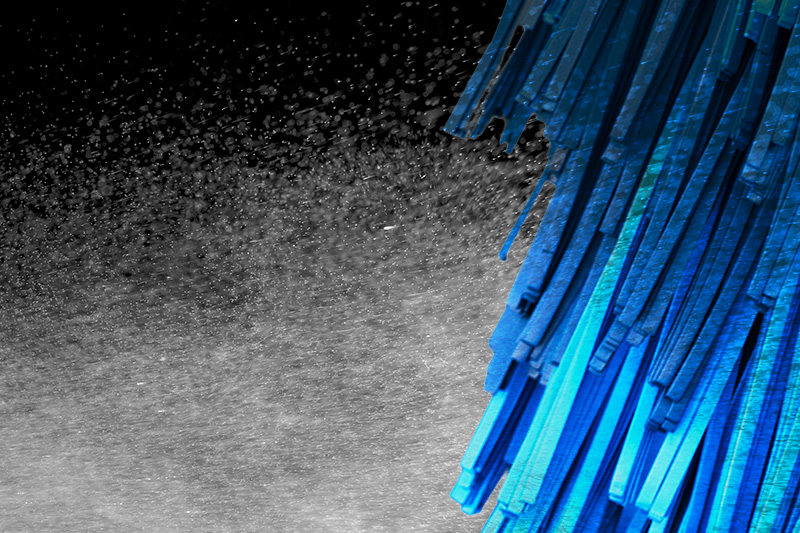

“Modern friction IBAs use a closed-cell foam material lubricated with shampoo and water that glides easily over the vehicle surface and sheds dirt during the brushing process,” Robinson says. “Both characteristics provide safety and a better cleaning quality.”

Hobby states that a combination of unique soft cloth and a closed-cell foam media delivers the best results that will satisfy the driver who stays in the vehicle during the wash cycle. This media is gentler, yet it still produces the wash quality that customers expect.

“Both media tend to polish the vehicle as it is being washed, which allows for effective and efficient cleaning without damage as long as the surfactant and lubricating effects of the wash solutions are maintained,” Hobby explains.

Inspect and maintain

Regular inspections and maintenance are necessary to ensure optimal equipment operation. Robinson suggests an operator run a test wash daily and observe to make sure all aspects of the washing and drying processes are performing as expected. While every wash wants to turn out clean, dry and shiny cars, many operators still fail to take this simple step at the start of each day. Even so, this testing is the best way to identify problems before they become critical and cause a loss of customers due to poor results.

Hobby advises all operators to visually check their sites daily as well. In unattended IBA operations, customers may discard trash indiscriminately, or trucks may enter a bay with debris in the open bed. These materials can be left in the bay after a truck exits due to blower operation.

The easy answer to any equipment maintenance question is: Follow the manufacturer’s recommended maintenance schedule. If wash equipment goes down, a location is not making money. Preventive maintenance is cheap insurance to minimize expensive repair bills and keep a site’s revenue flowing, Robinson states.

“Your IBA manufacturer and its factory-trained service technicians have years of experience accumulated over a broad customer base,” Robinson continues. “Let their experience, as embodied in their recommended maintenance schedule, be your guide.”

Hobby agrees that the most important steps to eliminate repairs and downtime are regularly scheduled preventive maintenance tasks. Manufacturer checklists are provided for operators based on their equipment configuration. As most IBA operations are unattended, the primary concern will always be keeping the premises clean, and this includes the equipment itself.

Chemistry considerations

Though brushes are used during these IBAs’ wash cycles, chemistry is still critical when washing with friction. Most of the chemistry’s color and fragrance are included for sensory impact. The reality is that the wash media must be properly lubricated constantly to prevent damage and provide effective cleaning, Hobby notes. Although the surfactants used in the lubrication process can be expensive, the overall net cost is much less than attempting to wash in a touch-free mode. Also, the cleaning performance will prove to be more consistent.

The need for a pre-soak differs based on weather considerations, according to Robinson. In seasons where vehicles are typically easier to clean, a separate pre-soak application may not be necessary. During seasons where vehicles are harder to clean, a pre-soak application may provide useful assistance.

Either way, the amount and cost of cleaning chemicals consumed by a friction IBA will be significantly less than a touch-free system. Once the surface’s dirt has been removed, the chemicals typically used during the finishing passes are the same for both friction and touchless IBAs, Robinson states.

“The overall cost per car for a given wash is less for a friction IBA, plus friction IBAs consume substantially less water during the cleaning passes, since high-pressure water is not required,” Robinson says. “The combination of less chemical and lower water consumption yields significantly lower total operating cost.”

Continued popularity

Today, well-maintained IBAs and tunnels can both turn out clean, dry and shiny cars, Robinson notes. For the end customer, the choice of which wash to use often comes down to price and convenience. IBAs are ubiquitous at gas stations because they have proven to be a convenient option. Whether a customer is buying gas or making a quick stop for snacks or beverages, if a vehicle is dirty, it can be an easy decision to complete two errands during one stop.

IBAs at carwash-only sites are convenient, but their use requires a conscious decision to make another stop just to wash a vehicle. An express tunnel is also a destination purchase, but the promise of a speedy wash and free vacuums — if offered — can provide extra incentives, Robinson explains.

“Some customers value low price over convenience and are willing to drive farther to save a few dollars,” Robinson reveals. “Other customers place a higher value on convenience and will pay more to avoid having to make an extra stop. In the end, it boils down to customer preference, and there’s strong consumer demand for both wash formats.”

Another market where IBAs have become extremely popular is with auto dealerships, Hobby states. This is due to the fact that this type of carwash normally requires a small footprint, but it can deliver a quality wash service without prep or labor. There have also been huge successes for IBAs in the retail environment, since the footprint of these washes can fit into a site with as little as one quarter of an acre.

Equipment cost is another consideration. Economically, smaller towns and markets can often justify this type of development, Hobby notes. Here, a multimillion dollar express tunnel requiring substantial real estate will not fit a location’s economics.

“We believe customers choose to use a wash based on experience, location, convenience and accessibility,” Hobby concludes. “In essence, the in-bay automatic, properly executed, can deliver superior wash quality without labor or on-site prepping of vehicles and has a phenomenal future in the profitable world of carwashing.”

Thomas Hawkins is a freelance contributor.