Over the last decade, many advances have occurred in the equipment and control space; however, site management technology hasn’t kept pace with innovation. As the sophistication levels have risen, developing a fully integrated solution for monitoring, maintaining and managing the critical components of a carwash operation has become increasingly challenging. The most sophisticated and fastest growing model is “express exterior,” which is essentially a motorized assembly line of robotic wash machinery, executing specific applications throughout the cleaning, shining and drying process.

From a servicing perspective, the skill level has risen as well. Today, technicians need to be multi-skilled, with industry-specific expertise in plumbing, electrical and mechanical systems, and on occasion, have some specialized

knowledge in fluid dynamics and computer programming. Mom-and-pop businesses are now fueled by private equity capital, which has catapulted the growth of chain operations and the need for qualified technicians across the U.S. Multi-unit operators stand to benefit the most from new technology, usually by way of operational efficiencies from store clusters.

For example, by leveraging remote management technology, a site or facilities manager can now manage more locations in the same time period without ever losing visibility or control of an individual site. This revolutionary “industrial internet of things (IIoT)” technology is now available to all operators. It works on all types of carwashes and any brand of equipment and controls.

Monitoring

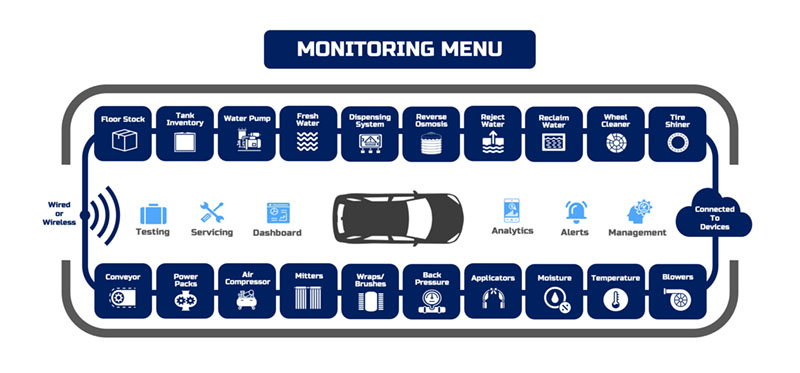

From a single-pane application that can be accessed from any desktop or handheld device, business intelligence data is collected from sensors connected to on-site devices in specific site zones — inventory, equipment, facility and service — with the ability to manage the data received. The standard technology package specifically monitors tank levels, fresh and reclaim water volume, water quality, air and water pressure, tunnel/bay, equipment room and outside temperatures, wash package counts and costs, car counts, the average cost per car, maintenance and routine

checklists.

Custom packages can also be created from the monitoring menu. All technology packages utilize artificial intelligence (AI) to generate predictive analytics. Customized parameters (low and/or high point) are established for each device (i.e., equipment), which controls “out of parameter” notifications (via text or email). See Figure 1.

Maintaining

Carwashes are like race cars — if they aren’t maintained properly, they will break and create losses in revenue due to downtime. With the help of a digitized service module, all maintenance items can be automated through completion. Additionally, case files can be created for incident reports and managed according to a customized checklist through

resolution.

Form checklists are available at various service frequencies (daily, weekly, monthly and yearly). For example, opening, closing, health check, site audit and ghost wash lists can be created for each location. Select standard operating procedures, or SOPs, are provided for some preventative maintenance items, which can also be used for training purposes. In addition, custom checklists and SOPs can be created. All service items can be based on a specific time period or by wash cycle and all tasks can be assigned to an individual or role within the organization or third-party vendor. See Figure 2.

Managing

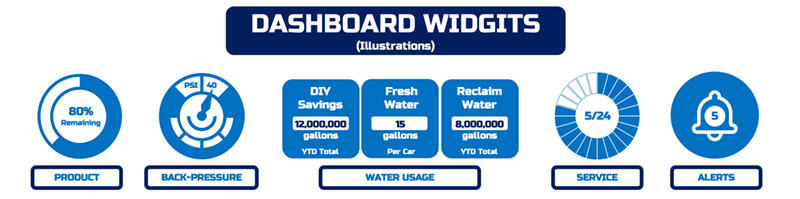

The app offers remote management from a desktop, tablet or smartphone. From one consolidated dashboard, all business intelligence data is organized and displayed by module (inventory, equipment, facility and service) within a dedicated container. This technology tool provides managers with site-specific visibility and control in real-time, allowing for proactive data-driven decisions.

Examples include:

- Services not completed by a set deadline

- Over or under usage of chemicals, detecting a leak or clog

- Water quality degradation, low tank or floor stock

- Other equipment/device out of an optimized parameter.

Managers receive a warning shot/notification of an impending issue without having to be on-site. In addition, business insights can be surmised from key performance indicators and reporting functions for each module. Other intuitive features include auto replenishment and water usage. Technology will enhance operational efficiencies and protect against downtime. See Figure 3.

Outlook

Early adopters of technology stand to realize more operational efficiencies while maintaining a competitive advantage over other carwash chains. Having a dashboard that monitors all the critical components of the operation allows for effective and efficient site management. Leveraging the power of this technology increases the visibility and control over the facility, inventory, equipment and service. This ultimately leads to more uptime, labor savings, throughput, profits and smarter decisions. SmartOperators are early adopters of technology and leverage the competitive advantage(s) it creates.

Michael O’Donnell is a 37-year veteran of the carwash industry, touching every aspect of the business, inclusive of: ownership, operations, technician, instructor, product development, equipment sales, distribution and manufacturing. He is a principal with Newport Beach, California-based Smart Solutions Inc., an innovative “fluid technology company” serving the professional carwash industry, specializing in advanced chemistry, technology and support. Learn more at smartsolutions.net or contact Michael O’Donnell at [email protected].

Be sure to check out our follow up video interview with the author, Michael O’Donnell in the video interview below.